| Model # | Description | Length | Width | Height | Ship Wt.(lbs) |

|---|---|---|---|---|---|

| SBH-2-P | 35 1/4" | 43" | 300 | ||

| SBH-2-WB | 35 1/4" | 43" | 300 | ||

| SBH-2-PWB | 35 1/4" | 43" | 300 | ||

| SBH-3-P | 35 1/4" | 43" | 425 | ||

| SBH-3-WB | 35 1/4" | 43" | 425 |

APPLICATION

SBH Series are self-leveling heaters and dispensers for plates and heat retentive devices (our Diamond D-8000 wax base) used in tray make up systems. An adjustable thermostat makes the unit compatible for low and high heat applications.

Only Piper's equipment has the advantage of FoodSafe technology and certification. This ensures that your food is kept "out of the DANGER-ZONE." Food spoilage occurs mainly because of rapidly accelerated bacteriological activity within the 40F-140F "DANGER-ZONE."

With FoodSafe hot food stays above 140°F longer and cold food is kept below 40°F. Both are key factors in HACCP compliance and the fight against foodborne pathogens.

STANDARD FEATURES

- Heavy-duty 304 high nickel 18-8 stainless steel construction

- 5" Swivel Plate Casters

- Full perimeter bumper is standard

- 3200 watts of converted forced air heat for faster heat up (thermostatically controlled)

- Field adjustable thermostat

- Gasketless lid seal design to maintain heat

- Self-leveling, field adjustable spring dispensing design allows easy access to bases & plates

- Two & three silo configurations

- Holds 90 or 135 Diamond D Series wax bases - other base configurations may vary in quantity

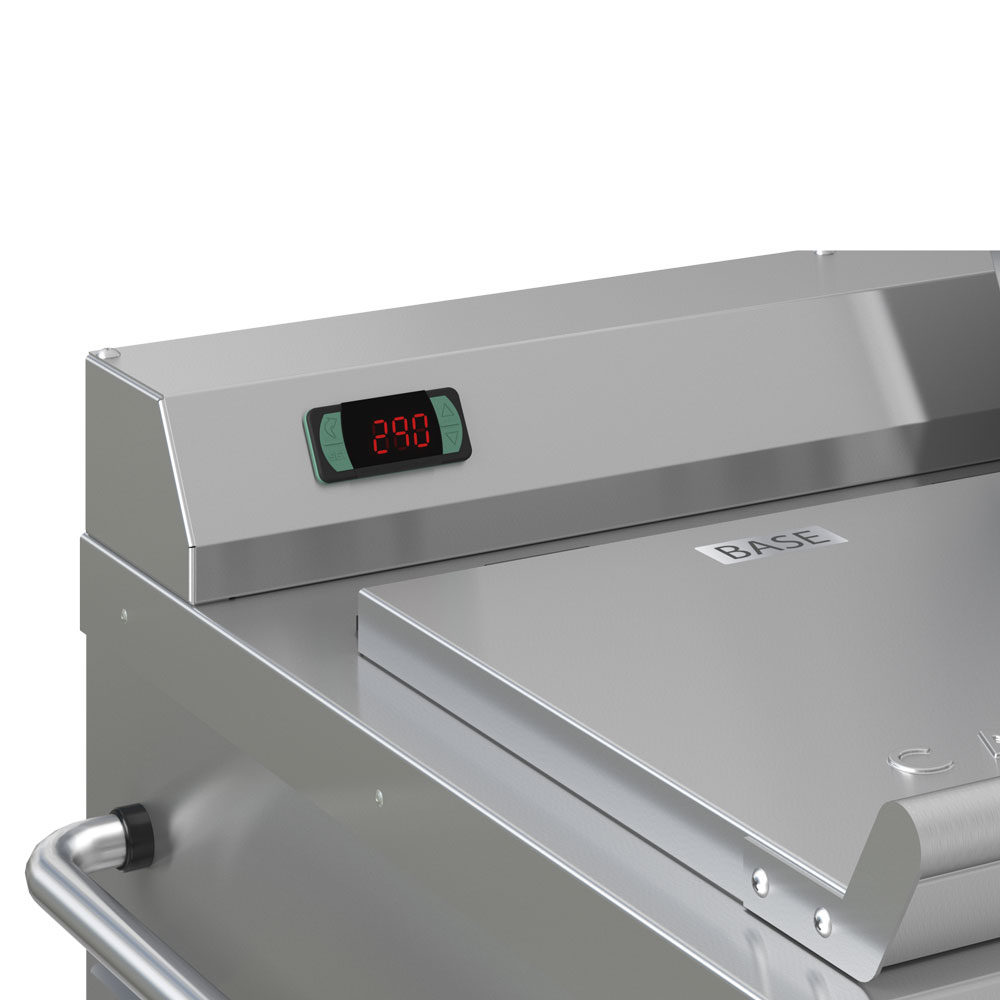

- Exterior control protection hood

- Hinge-less lid

- Lid hangers

CONSTRUCTION

The exterior shall be constructed of 304 high nickel 18-8 stainless steel with the frame constructed of 18-gauge, the side and front panels constructed of 20-gauge, the back panel constructed of 16-gauge and the base constructed of 14-gauge with a "H" frame reinforcement of formed "U" channel construction. Two (2) and three (3) silo models shall be available. Each tube shall hold approximately 45 bases or plates.

The fully insulated lids shall be constructed from 16-gauge stainless steel with a gasketless design. Lids have no hinges and can be hung on brackets during operation.

The full perimeter bumper designed with a bottom stainless steel reinforcement bracket to allow heavy long term use and 5" polyurethane non-marring swivel casters (2w/ brakes) shall be standard.

The heating system shall be a forced air convection design that circulates thermostatically controlled super heated air evenly through the fully insulated cabinet. The dual voltage unit shall be designed to draw 3200 watts at 240 volts with 13.5 Amps and 3000 watts at 208 volts with 14.5 Amps.

CONTROL SYSTEM

Thermostatic controls to maintain the bases at 225°F. The heating system recirculate the hot air horizontally to ensure rapid and efficient heating of the bases. Full heating of the bases is accomplished in 75 to 90 minutes.

Initial heat-up of a fully loaded unit shall be approximately 2 hours or less with reheat cycles to be 1-1/2 hours depending on wax base design.

File Downloads

| File | Description | Size | |

|---|---|---|---|

| F-1.PDF | SPEC: Unitized Base and Plate Dispenser Heated | N/A | |

| SBH Manual.pdf | SBH Manual |

1.78 MB | |